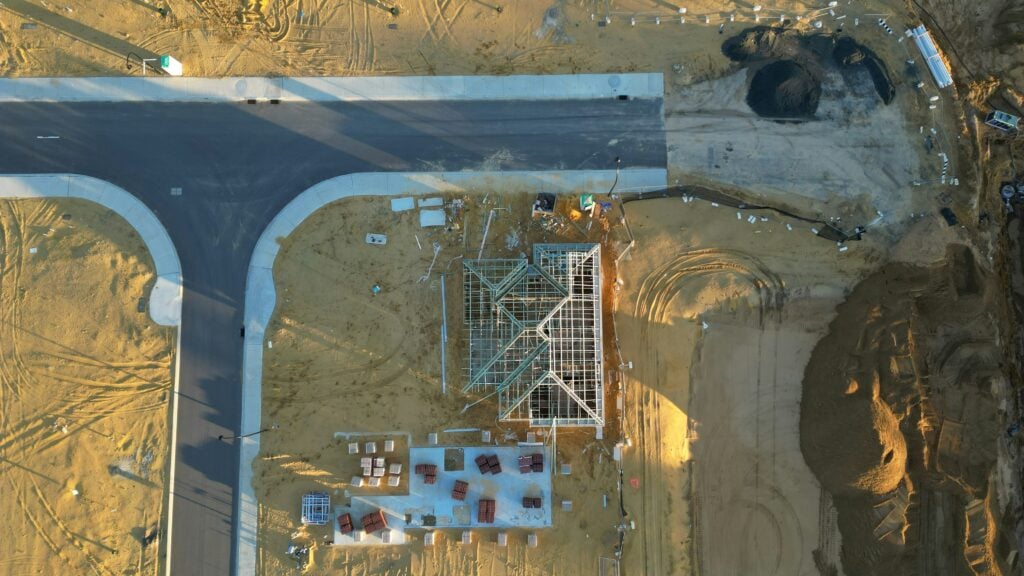

We’ve seen projects stalled or even abandoned when late-stage geotechnical surprises (such as weak soils, waterlogging, buried waste or rock) add huge costs or design constraints.

A thorough site investigation (consisting of both desk study and intrusive sampling) gathers the hard data to confirm or rule out risks and protect the project from unforeseen costs, planning delays, or environmental liabilities.

In short, the best time to understand ground conditions is before buying land or submitting detailed plans, not after a problem appears.

What is a Site Investigation?

A site (ground) investigation is the process of collecting and interpreting data about the ground beneath a proposed development. It typically starts with a desk study, reviewing geological maps, old site plans and history, and proceeds to physical testing of soils and groundwater.

In practice, our site investigations follow a staged approach:

- Phase 1 (Desk Study): Gather all existing information (site records, borehole logs, geology maps, historical land use) to identify potential risks.

- Phase 2 (Intrusive Investigation): Drill boreholes and dig trial pits to sample soils, groundwater and any contaminants in situ. Standard methods include cable-percussion or rotary drilling, window sampling, and excavation of pits for shallow layers.

- Laboratory Testing: Send collected soil, rock and water samples for tests (strength, density, contaminants, ground gases, etc.) to quantify hazards.

- Phase 3 (Further Field Work): If needed, return to the site (detailed pits, monitoring, additional drilling) based on initial findings.

- Phase 4 (Reporting): Compile an interpretive report that assesses bearing capacity, settlement, contamination and water issues. Engineers then use this to design foundations, earthworks and drainage.

Well-planned investigations save money by giving engineers the data they need to optimise design. For example, defining the exact location of weak soils can reduce the extent of expensive stabilisation layers or imported fill, potentially cutting earthwork volumes by a significant amount and offsetting the cost of the investigation. In short, you pay for an investigation one way or another.