Webinar: Value Enhancement on Civil Engineering Schemes

Richard Moorcroft, Group Operations and Engineering Director, and Siobhan Murphy, Technical Director, explored the challenges in unlocking long-term value across the lifecycle of a complex civil engineering scheme, sharing the lessons and tips they felt could support future schemes.

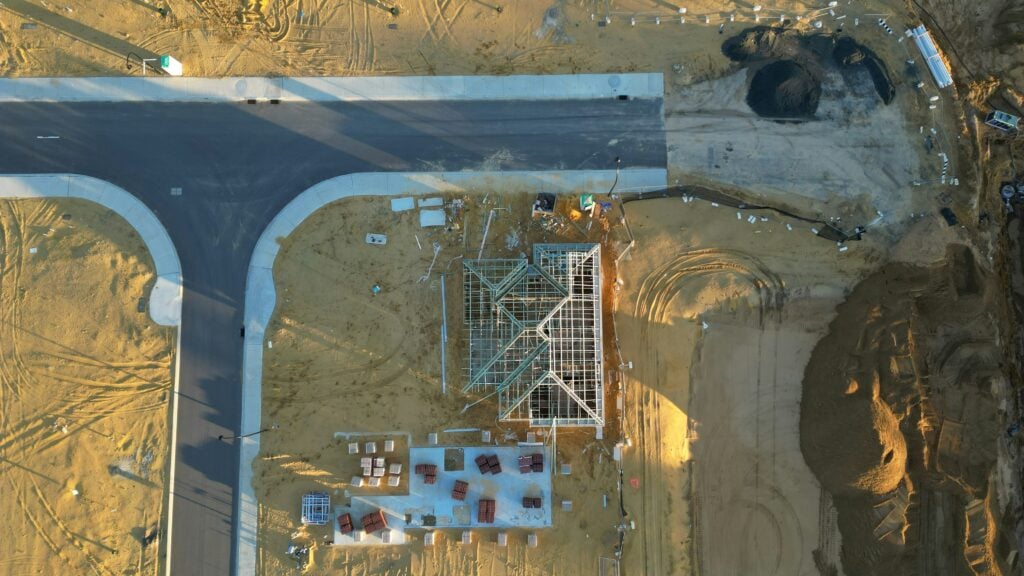

Eastern Green, Coventry, A45 HIF Works

Background

- The A45 is a strategic highway linking Coventry & Birmingham

- Dual carriageway, national Speed limit route

- Urban environment with significant constraints

- Traffic flows necessitated a grade separated junction for primary access

Scheme Involves

- C. 2km of new highway with associated drainage

- Three new roundabouts, slip roads with the A45

- A new bridge over the A45

- 4 no. culverted watercourse crossings

- Utility diversions

- New service supplies to serve future phases

Constraints

- Areas of Flood Zone 2 and 3 – Pickford Brook

- Extensive utilities within the A45 corridor

- Two no. extra high voltage over head lines

- Existing vegetation

- Great Crested Newts

- Badgers

- Archaeological finds

- Prevailing site levels

Roles & Responsibilities

Brookbanks

- Lead designer in pre contract phase

- Commercial & Project Management

- Contract administrator

- Employers Agent

- Principal Designer (CDM)

Breheny

- Principal Contractor

- Lead designer during construction phase

Strategic Oversight and Collaborative Design: Brookbanks’ Role in Pre-Construction and Project Management

The pre-construction phase of the project was led by Brookbanks, who played a central role in both civil design and overall project management. Supported by funding from Homes England through the Housing Infrastructure Fund (HIF), and in partnership with Coventry City Council, the project required careful coordination and transparent communication to maintain stakeholder confidence.

Homes England received regular updates on progress and forward planning, ensuring continued trust in the appropriate use of funds. Following a judicial review of the planning consent, project milestones were renegotiated and agreed upon with Homes England, resulting in a revised but realistic programme. Site visits by Homes England during the construction phase further reinforced accountability and transparency.

The design process was a collaborative effort involving Brookbanks as the lead for civil design, Pell Frischmann for bridge, geotechnical, and culvert design, and Coventry City Council for street lighting. Weekly progress meetings ensured alignment across all teams, and the design brief—covering parameters such as bridge type, span, width, and materials—was agreed early in the process to guide technical development.

Departures from standard design practices were necessary due to site-specific constraints, such as the proximity of junctions to existing access points. These deviations were discussed and approved early on with Coventry City Council, ensuring compliance and smooth progression through the planning and design stages.

Commercial Process

Tendering the Works:

- Tendered in collaboration with Coventry City Council – OJEU process(public procurement rules)

- Design & Construct Contract to maximise risk / reward opportunities

- Breheny granted preferred bidder status to permit start of ECI phase

Commercial Process:

- HIF budget of £15.6M as of 2019

- Construction works forecast cost £21.1M as of May 2021

- Savings promoted through the initial ECI phase

- But:

- Rising cost of materials and inflation

- Materials & labour shortage, supply chain increases

- Covid Pandemic

- Scheme costs would have been far higher without VE / ECI phase

Value Engineering: Practical Measures for Cost and Time Efficiency

Breheny’s value engineering strategy focused on identifying practical, cost-saving measures that also support long-term sustainability and efficient delivery. For earthworks, all fill material was sourced from a borrow pit located on land designated for future sports pitches, preserving development potential while reducing import costs. In drainage, the use of UPVC materials for sewers accelerated installation and reduced build time. Precast concrete elements, including manholes and culverts, further streamlined construction, while negotiations with the Environment Agency enabled the removal of free-span bridges, simplifying structural requirements. Bridge design was refined by reducing span and width, and incorporating weathering steel and integral bridge structures-both of which require minimal maintenance and eliminate the need for painting or bearings. Street infrastructure was also optimised by reducing the use of passively safe lighting equipment and avoiding unnecessary street furniture such as fencing and signage, contributing to a cleaner and more efficient urban environment.

Challenges & Solutions

- HIF Funding milestones – Supporting Hallam Land & Coventry CCin agreeing sensible dates.

- Targeting the HIF funding at the critical infrastructure to open upthe primary access.

- Fast tracked technical approval process via weekly meetings withCoventry City Council and Breheny.

- Phasing the works with Breheny to open up an access from thewestbound carriageway into the employment area / Phase 2.

- Rising cost of construction materials (steel / red diesel)

- Illumination of the highway works (to permit adoption) ahead ofthe primary sub station being energized

- Materials management strategy. Infill the borrow pit witharisings / topsoil to avoid exportation

Integrated Approach to Infrastructure Delivery: Breheny’s Collaborative Model

Breheny’s early involvement in the design phase of infrastructure projects has proven instrumental in enhancing construction feasibility and cost-effectiveness. By working closely with design teams from the outset, Breheny ensures that selected solutions are practical and economically sound, streamlining the transition from design to construction.

Strategic Design and Environmental Efficiency

Key examples of Breheny’s value-driven approach include the culverting of watercourses as an alternative to bridge construction, and early utilities and site investigations. These measures enable the use of site-won materials for earthworks, reducing environmental impact and promoting sustainability.

Quarrying, testing, and validating site-won aggregates for permanent works significantly reduce lorry movements on major roads such as the A45, lowering carbon emissions and minimizing disruption to local traffic.

Comprehensive Scope and Stakeholder Engagement

Breheny’s scope encompasses earthworks, drainage, road construction, structures, lighting, signage, attenuation ponds, and habitat creation. The company excels in managing interfaces with Coventry City Council, local businesses, and residents, ensuring smooth coordination and minimal disruption.

Co-location of client and delivery teams fosters real-time collaboration, while the programme is meticulously developed during tender and value engineering stages. Time risk allowances are built in for contractor-held risks, and constraints such as ecological factors and major events (e.g., the Commonwealth Games) are proactively considered.

Programme Management and Risk Mitigation

The construction programme is aligned with the pricing document activity schedule and serves as the basis for cashflow forecasting. It is baselined to track progress and is continuously updated to reflect real-time developments and delays.

Seasonal variations are accounted for in activity outputs, ensuring realistic scheduling and delivery expectations.

Technical Excellence and Sustainable Practices

Breheny addresses complex challenges such as utility diversions near critical structures, including large water service pipes and fibre optic cables. Temporary works are carefully designed to facilitate safe and efficient construction.

Surface water management is handled through innovative systems like new ditches and de-siltation processes. Collaboration with designers and suppliers ensures procurement of high-specification, bespoke materials tailored to project needs.

Meet Richard and Siobhan...

Richard Moorcroft

Read Profile

Siobhan Murphy

Read ProfileCheck out the Civils team...

Civil Engineering Group

More News

Delivering EV Charging Infrastructure: Helping Developments Meet Today’s Demands and Tomorrow’s Expectations

February 25, 2026

At Brookbanks, we know EV charging becomes far more manageable when it’s approached as part of a wider development picture rather than an isolated task. Rising regulatory demands, limited capacity, cost pressures and the realities of underground or enclosed parking all interact in ways that can affect programme, viability and long‑term performance. This article looks at the recurring challenges we see across residential, commercial and mixed‑use projects and the practical steps that help developments meet Part S requirements, manage grid limitations, integrate load‑balancing and smart‑charging systems, and plan for solar PV and battery storage. The aim is to provide clear, grounded insight that helps teams design EV strategies that genuinely stand up to modern development demands.

Our February 2026 Newsletter

February 23, 2026

Welcome to our February 2026 newsletter. In this issue, we will be sharing what’s been happening over the past month, including our two new podcasts highlighting the common pitfalls around S278 and S38 highway approvals, and what the Planning & Infrastructure Bill means for developers in England and Wales, with special guest Mark Harris from HBF Wales. We’re also looking back on our latest article, which explored how unspent S106 and CIL funds create opportunities to review, challenge and optimise legacy obligations, and why combining planning expertise with commercial insight is key to unlocking value. Plus, we are rounding off by showcasing one of our team's achievements.

Brookbanks Webinar: De-risking Infrastructure Design

February 18, 2026

Earlier this month, we hosted a lunch-time webinar exploring how infrastructure design can be strengthened well before construction begins. Led by our Civil Engineering specialists Ryan Meade and Toby Crayden, the conversation focused on the practical steps that help to reduce uncertainty and make the transition from design to delivery smoother and more predictable. Their session looked at the real‑world challenges that commonly appear between early drawings and activity on site. Ryan and Toby shared their experience of how early awareness, clearer coordination and the right conversations at the right time can make a measurable difference to project outcomes.